The classic Stelbel fork crown

The fork crown has long been a hallmark of all Stelbel frames. Handmade without prefabricated parts, its construction is time-consuming and demanding, and an example of great craftsmanship.

Following Stelio Belletti’s directions to the letter, it was possible to reintroduce this characteristic detail today when producing classic models.

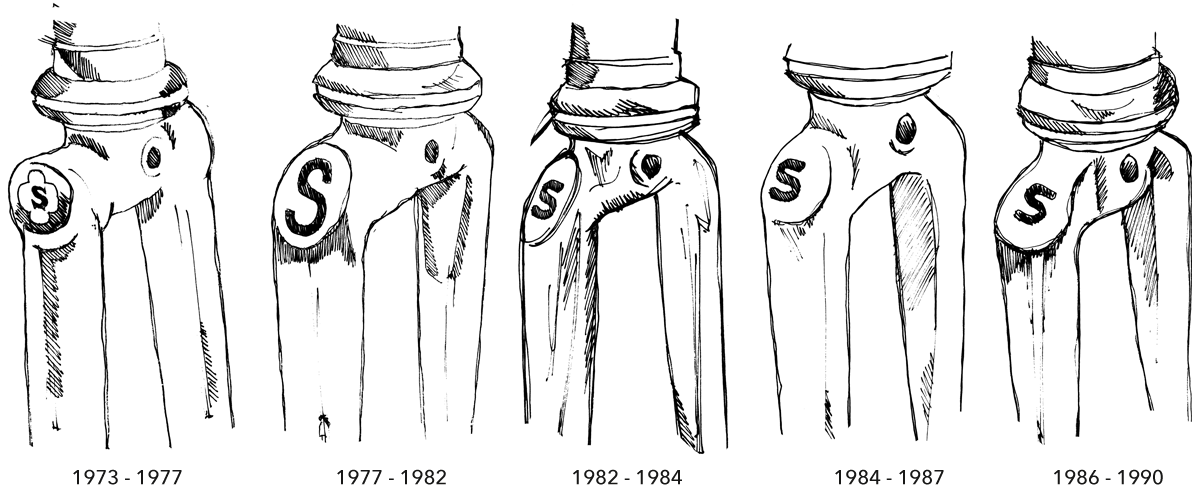

Its design has changed several times over the years, and is divided into at least five different generations as well as several special achievements.

Knowing how to recognise the generation of the fork crown is the easiest way to identify different periods of construction of a frame.

Worth noting: The description and the dating of different generations is extremely accurate and verified by numerous cross-checks, but given the bespoke, customisable nature of Stelbel’s production methods there are exceptions and special cases. Moreover, the introduction of a new generation of fork crowns didn’t always immediately spell the end for version from previous generations.

First generation, 1973 – 1977

The first version of the fork crown built by Stelio Belletti has no letter or logo engraved or stamped on the side faces. This forks have welds that have not been filed, with stickers bearing the logo on the lateral faces of the head. They may be concave or flat with a circular shape and welded vertically or perpendicular to the ground. After 1976 the welds were filed and the faces of the head tilted.

Second generation, 1977 – 1982

Introduced on Integrale models from 1977. Its outer faces are tilted, with the letter “S” of rounded shape engraved or printed. There are reinforcements present on the top and inside of the fork blades that can either be visible or done internally. This was the longest produced generation of fork crown, and it featured on models until the early’ 80s, probably until 1982. This is also the version we’ve used on the modern Integrale 40th anniversary model.

Third generation, 1982 – 1984

Beginning in 1982, the shape of the iconic “S” on the changes, becoming smaller and squarer. The differences in construction of the head are not very perceptible. Reinforcements of the blades are now always internal and not visible, and the diameters of the tubing used for the construction are slightly thicker.

Fourth generation, 1984 – 1987

At the end of 1984, this generation was introduced with the head featuring convex faces, created by moulding a piece of sheet steel. The iconic “S” stays the same.

Fifth generation, 1986 – 1990

From 1986, the technique of joining tubes changes radically. The blades are welded directly to the steerer tube, which is suitably reinforced. This design was often used for forks that fit wheels of smaller diameters.

Special cases

- There was a period of transition for the pantographs between the second and third generations in 1982.

- Unicrown forks, made sparingly from 1987, as required by “Capella Cicli” of Turin.

- Straight bladed forks, made from 1987 in stainless steel

- Square-style engraving of “S” from 1987

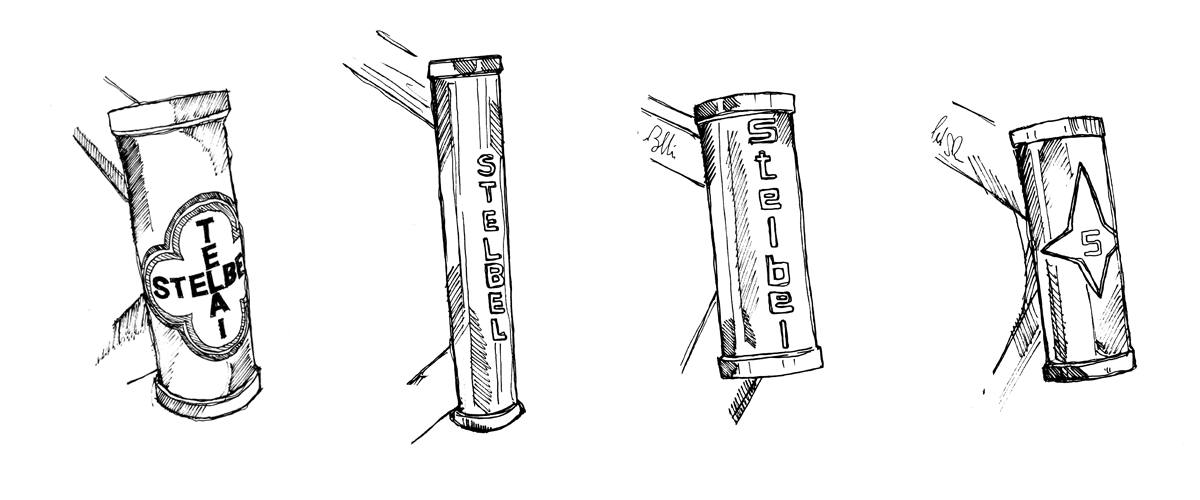

Headtube engraving

Often the most obvious method for recognising an original Stelbel is the iconic engraving on the headtube, with the brand’s classic font arranged vertically. This detail, however, was introduced as we know it only in 1978, so all frames built between 1973 and 1977 will not feature it. There are also models that Stelbel built in 1978 that do not featured the engraved headtube. In these cases, the “cloverleaf” logo was almost always applied.

Between 1977 and 1979 there are also some examples of prototype engravings, on which the characters differ slightly. By 1980, the style became definitive and is still visible today on our models.

There is also a rarer style of engraving detail found on some Stelbel frames that was introduced along with the model Punta dell’Est in 1983. It’s a four-pointed star within the letter “S” at the centre. This design was used between 1983 and 1987, almost always on time trial bikes.

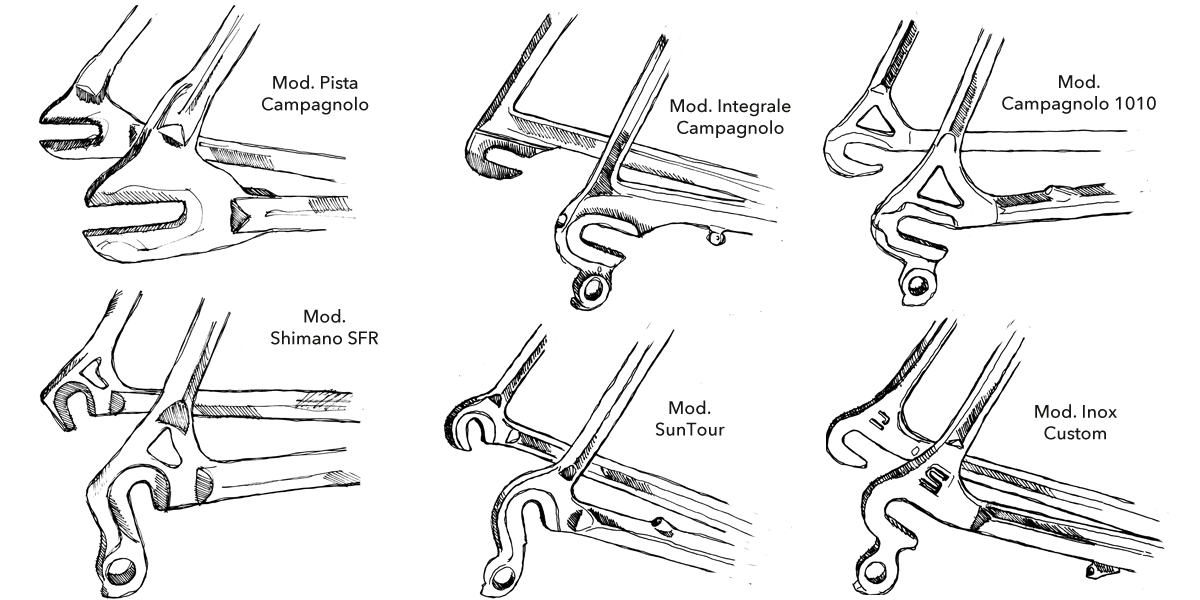

Rear dropouts

Stelio Belletti has always attached great importance to the design of his rear dropouts. The evolution of this particular part of the frame has always been of interest to us, and over the years, unique solutions have been created that were forward-thinking for the time, and often miles ahead of the competition.

Integrale Dropout

Another unique Stelbel design, this dropout has characterised the Integrale frame since its introduction in 1973, and with the next official patent in 1975. It is a classic Campagnolo dropout, shaped and modified to be welded onto the rear stays.

On certain models from the period, this design also introduced the principle of the self-centring dropout, which did not allow for the adjustment of the wheel axle. This result was obtained by profoundly changing the length of the dropout itself, thereby reducing the possible stroke. This dropout design is still used for the construction of our 40th anniversary Integrale model, but today we use the more common version which allows for wheel adjustment.

Campagnolo 1010 Dropout

Without doubt the most common dropout for racing frames in the 70s and 80s, this is the model that was modified by Stelio Belletti for use on the Integrale. Featured on Strada and Strada Super models since 1979, this is still used on our modern Super Strada range today, though no longer provided by Campagnolo.

Shimano SFR Dropout

Stelio Belletti is also remembered for being among the first manufacturers to use vertical dropouts. The first examples are traced back to 1977 with the introduction of the Shimano SFR. Frames with this type of dropout are especially rare because of little demand from customers at the time, who mostly preferred dropouts that would provide for the adjustment of the the wheel’s position.

SunTour Dropout

A vertical dropout, the SunTour SDB-EF120 was often used for our Dynamic models, as well as Cronotime and Cronosquadra frames between 1983 – 84.

Track Dropout

For Stelbel track frames built in the 70s, Campagnolo Pista dropouts were almost always used, while from the 80s it was also common to use Gipiemme track dropouts.

INOX Dropout

For Stelbel’s earliest stainless steel frames, the ubiquitous Campagnolo 1010 dropout was used. Before long, however, Stelio Belletti developed his own design for a dropout in stainless steel, and began using it in 1986. These dropouts were made from a thick piece of metal that was laser cut to shape, and upon which the “S” was branded in a style resembling a lightening bolt.

Evolution of the brand’s logo and decals

Stelbel’s graphics and branding have always been as innovative and exciting as our frame technology, and our bikes have always stood out from the rest of the crowd.

The classic logo design originally introduced in 1978, and hasn’t been changed much to this day, but there are variants used in construction prior to that year.

In the early days of Stelbel, decals weren’t available and all branding was simply painted onto the frame with the aid of masking. That changed in 1974, when the first official series of Stelbel decals, adorned the early Integrale models.

The Stelbel script on the downtube was in block and inserted inside a white rectangle with rounded edges at the ends with the Italian tricolour. On the head tube, and sometimes on the seat tube, early versions of the “clover” logo sometimes featured. On it, the words “Stelbel” and “Frames”, crossed each other through the centre, sharing their respective central letters, “L”.

In 1976, the second version of the logo was introduced. The design is very similar to the present one, and it anticipated the final move to merged letters. In most cases this logo was used in black, with the outline done in gold.

Towards the end of 1978, the logo we know today was introduced. In most cases, this logo is done in yellow with a black outline, or white with a black outline. In the ’80s, several new different colour combinations were introduced, although the yellow and white variants remain the most famous.

The introduction of the Dynamic models in the early 80s added some more graphic elements, dedicated especially for that series of frames.